I.Project Overview

On 22, July, 2025, SIYI partnered with a local agricultural cooperative in Huizhou, Guangdong to perform a precision crop protection mission covering 1.42 hectares of rice fields. The mission was carried out using SIYI’s E6 Integrated Propulsion System installed on the EFT E610P 10L hexacopter UAV, which successfully completed pesticide application under challenging weather conditions, including high temperatures, high humidity, and intermittent rainfall.

Mission Context:

• Crop Type: Rice (during the jointing-to-booting stage)

• Mission Type: Pest and disease control (pesticide spraying)

• Area Covered: 1.42 hectares

• Location: Huizhou, Guangdong Province

• Mission Timing: July 2025, during the monsoon season

• Challenges:

• High ambient temperatures (up to 37°C)

• High humidity (up to 78%)

• Intermittent showers

• Complex terrain with field dikes and irrigation channels

• High precision required for spraying and hovering control

II.Equipment Configuration

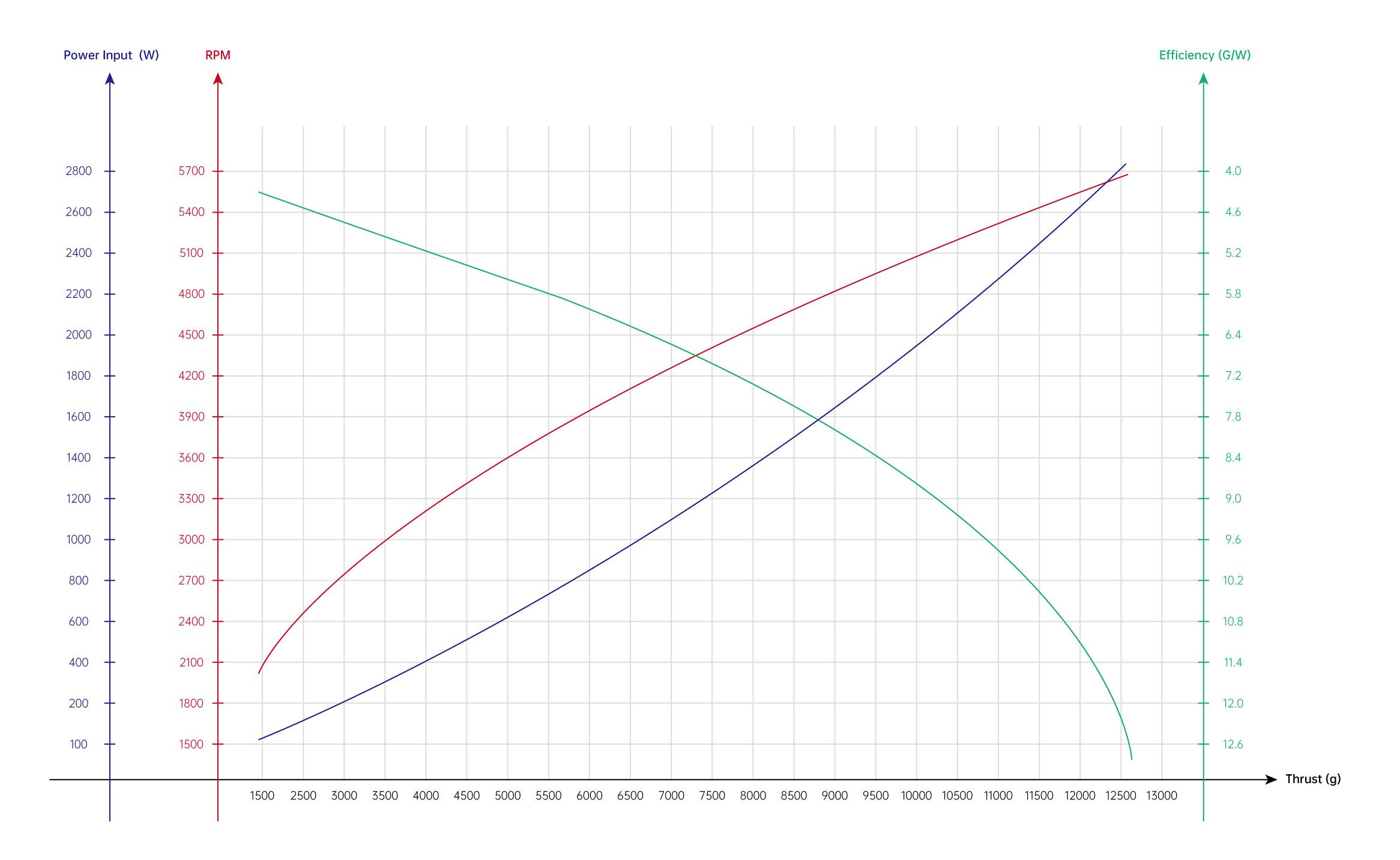

Propulsion System - SIYI E6 Integrated Propulsion System

• Key Features:

• Max Thrust: 12.5 kg per axis

• Recommended Payload: 10–13 kg

• Compatible Wheelbase: ≥900 mm

• Ingress Protection: IPX6

• Operating Temperature Range: -20°C to 60°C

• Components: High-efficiency brushless motors, FOC ESCs, and folding carbon fiber propellers

• System Advantages: High thrust-to-weight ratio, durability, and weather resilience, making it ideal for agricultural UAVs operating in harsh environmental conditions.

UAV Platform

• Model: EFT E610P (10L Agricultural Spraying UAV)

• Ground Control Station: SIYI MK15

Spraying System

• Spray Nozzles: XR11001 flat fan nozzles (×4)

• Spray Width: 3.5–4.0 m

• Flight Height: 2.2–2.5 m

• Flight Speed: 4.5 m/s

• Spray Rate: 22.5L/hectare

III.Operational Process & Execution

1. Flight Planning

• Partitioned 1.42-ha field into 3 operational zones

• Mapped avoidance geofences (ditches/ridges)

• Adjusted spray angle/speed for real-time wind

2.Field Operation Process

Step 1: Pre-flight System Checks

A thorough inspection of the UAV’s power system (motors, ESCs, and battery), and the spraying system (calibration and flow checks) was completed before takeoff.

Step 2: Payload Launch

The UAV was loaded with approximately 10L of pesticide per mission. The E6 power system allowed for smooth and stable lift-off, even under full payload conditions.

Step 3: Autonomous Spraying Operations

The UAV followed pre-planned flight routes using autonomous navigation, with the E6 power system maintaining constant thrust, ensuring the UAV remained stable and adhered to the flight path. The high-efficiency motors and FOC ESCs ensured smooth operation in the fluctuating air currents caused by high temperatures, maintaining precise spray application across the entire field.

The spray system was integrated with real-time flow control to adjust the spray rate as per the pre-programmed settings, ensuring uniform application without overlapping or under-spraying.

Step 4: Temperature & Humidity Adaptability

The UAV operated continuously for up to 35 minutes in ambient conditions of 37°C and 78% humidity. The E6 power system demonstrated excellent performance with no signs of power degradation or overheating. The high-efficiency design of the system contributed to stable energy consumption, ensuring the UAV remained within safe operational parameters.

Step 5: Post-mission Data Collection

Once the mission was completed, the system generated a spray coverage report and flight path data. The coverage rate was 99% based on GPS and spray calibration data, confirming the operational efficiency and precision of the spraying process.

Step 6: Equipment Maintenance

At the end of the mission, the UAV was cleaned using high-pressure water rinsing, thanks to the IPX6-rated sealing, which protects the UAV’s components from pesticide residue and ensures the longevity of the system.

IV.Conclusion: SIYI E6 Key Advantages

The E6 Integrated Propulsion System demonstrated exceptional performance throughout the mission, particularly in handling the challenges of southern China’s unpredictable weather conditions. The system’s combination of high thrust capacity, precise flight control, and weather-resistant design proved essential for successful agricultural UAV operations. Key takeaways include:

• High Power Reserve: Supports heavy payloads with consistent power, ensuring long-duration, full-load operations.

• Weather Resilience: Reliable performance under extreme heat and humidity, and intermittent rain.

• Precision Spraying: Seamless integration with flight control and spray system for accurate pesticide distribution.

• Low Maintenance: Modular, easy-to-service design, and resistant to environmental contaminants.

This case reinforces the E6 power system's role in enabling precise, large-scale agricultural UAV missions, providing both reliability and efficiency in demanding field conditions. Moving forward, SIYI Technology continues to drive innovations in UAV propulsion systems, expanding the potential for smart, sustainable agriculture.

Scan to follow the official account